Case Studies

AddiFab has developed a pioneering 3D printing technology that results in short lead-times, low start-up costs and design freedom for manufacturers across industries

AddiFab

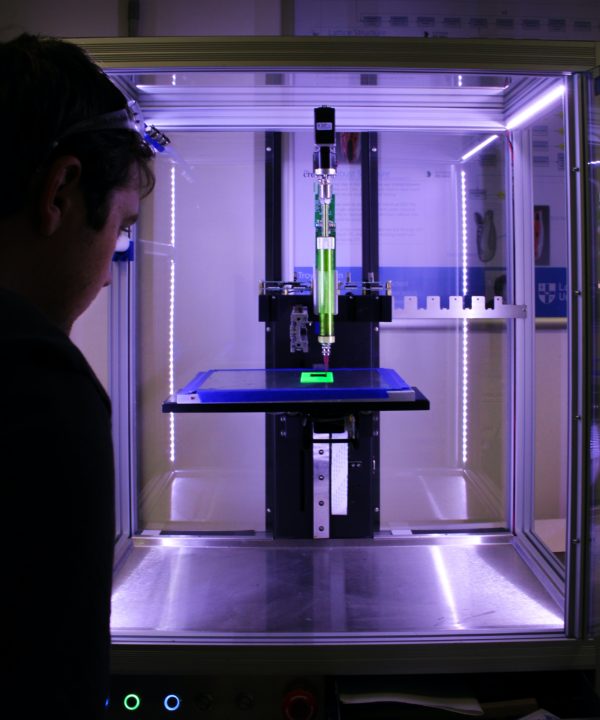

AddiFab has developed a highly innovative, versatile method of 3D printing injection mould tools that are used in the manufacturing of components for some very large consumer electronics, consumer goods and automobile companies.

AddiFab is pioneering Freeform Injection Molding, an innovative technology platform that brings the entire range of materials from the injection moulding industry into the world of additive manufacturing. Freeform Injection Moulding is the first 3D printed sacrificial tooling technology that enables manufacturers to produce complex products in a wide range of materials used in injection moulding, without the need for investment in hard tooling.

In the past, the lead time to produce a conventional metal injection mould could be as much as 100 days, costing tens of thousands of pounds. Addifab is able to 3D print an entirely new mould in any number of different materials substantially faster and at a much lower cost.

The Company was recently acquired by Nexa3D, the US developer of innovative 3D printing technology.

-

Capital Raising

£12m EIS equity

-

Investors

Principals of West Hill, HNWI, Ventures arm of Mitsubishi Chemical